Do you need help to know the properties of a material? Don’t know which material to choose for your product or need to change it? Your component has failed and you don’t know why?

In the Advanced Materials Characterization Laboratory we work on the development, characterization and modeling of materials – metals, technical polymers, elastomers and adhesives, paper and cardboard – whose properties play a fundamental role, at the functional level, in the behavior of components. The activities range from the experimental design of the materials, to adapt them to the needs and requirements of their operation in service, to the virtual and experimental modeling, for the evaluation and functional prediction of the components, structures or systems manufactured with them.

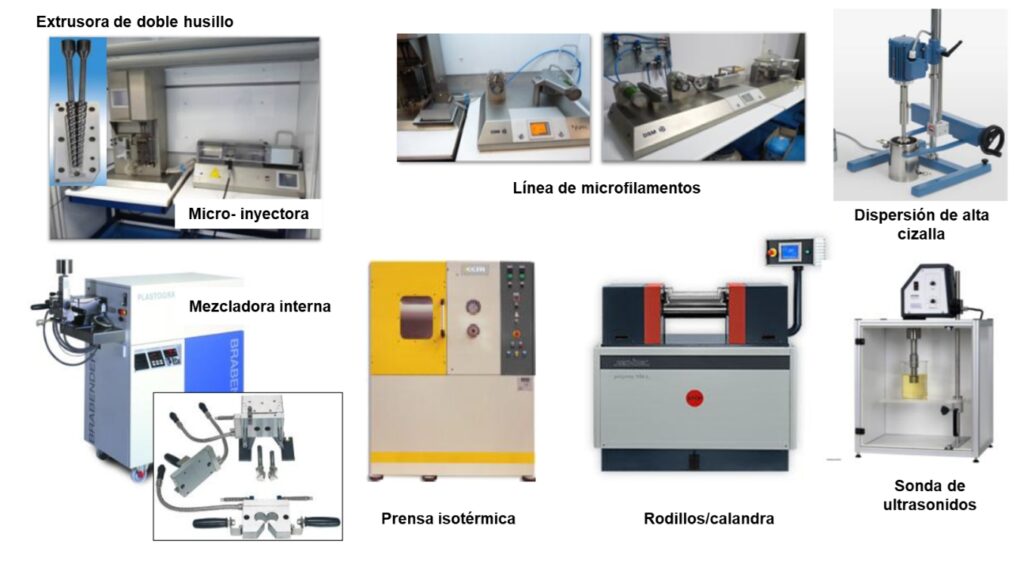

We develop knowledge related to the generation of composite materials with polymeric matrix additivated with micro or nanometric reinforcements, whose selection, mixing and processing strategies allow to provide the required properties to achieve a correct performance in service, with the characterization of their physical-chemical and mechanical properties as well as with the development and application of numerical modeling techniques for the analysis of the behavior of the materials, considering their processing and the different service conditions to which they are subjected, which we later use for the prediction of the functional behavior of the component, structure or system.

Dynamic and fatigue tests

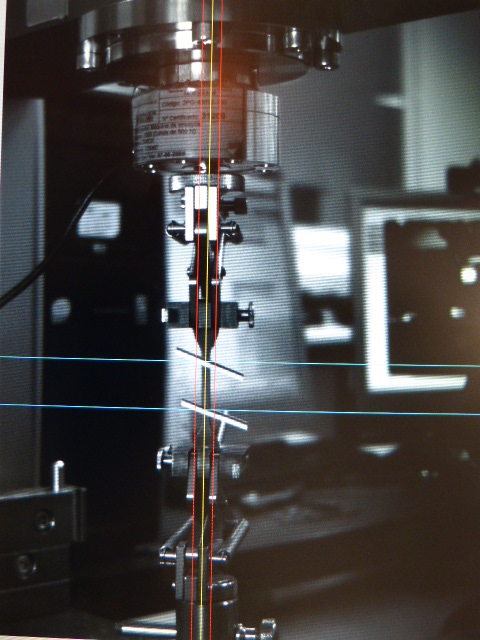

INSTRON Universal Dynamic Testing Machine – 25kN, 100Hz, with dynamic extensometer and climatic chamber from -70ºC to 250ºC.

Characterization tests of polymeric materials at different temperatures.

Static tests

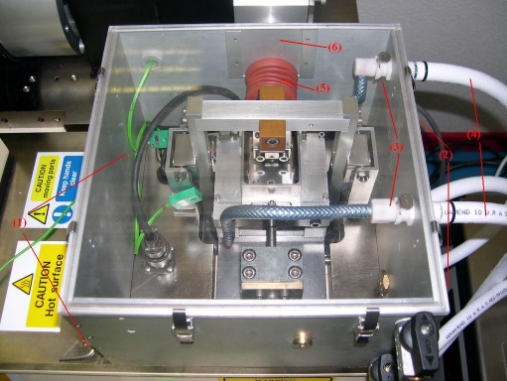

Viscoelastic properties of materials

Tribological characterization of materials (micro scale)

Fatigue crack growth monitoring

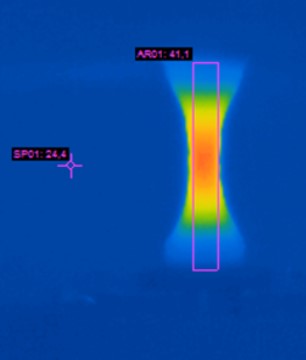

Temperature monitoring and hot spot determination.