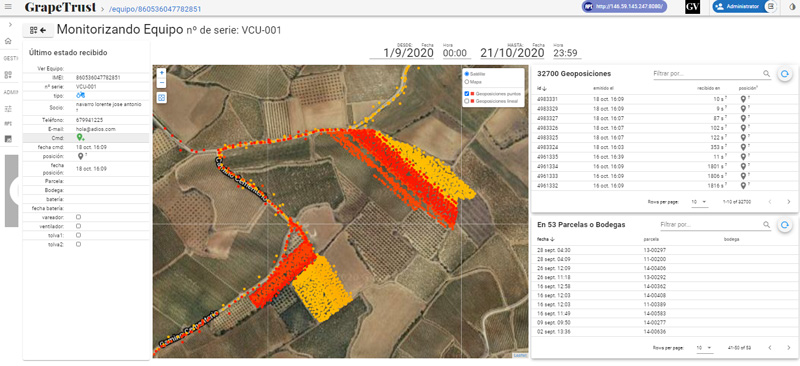

ITA has developed the project GRAPETRUST in collaboration with the company Grandes Vinos y Viñedos, whose main objective focuses on the control of harvesting operationsby the winery, through the monitoring of in real time of the location of grape harvesters and wagons used to transport the grapes, other data obtained from the grape harvesters and information contained in the grape harvesting transactional systems of the winery.

Grandes Vinos y Viñedos is part of the Cariñena Designation of Origin. The Cariñena PDO covers the Ebro Valley, with more than 12,249 hectares of vineyards. There are currently 33 wineries certified by this appellation of origin, which brings together 1,520 winegrowers and produces white, rosé and red wines, crianza wines, liqueur wines and vintage wines.

Grandes Vinos y Viñedos needs to control the main means used in the grape harvest, i.e. grape harvesters and transport carts, being able to control a series of parameters continuously, such as the position and its time reference associated individually to grape harvesters and carts or trailers. Optimization of the The quality of the wines produced in the winery depends on the quality of the grapes harvested at the optimum moment, as well as the quantity of grapes harvested in each of the plots, which is a key factor in the optimization of the harvesting process and of the products.

For this purpose, ITA has developed a solution of IoT(Internet of Things) Product Development which encompasses the development of a complete IoT platform that integrates from the devices of data capture in the harvesting operation (located in grape harvesters and transport carts), the resilient communication system considering the location of the plots of land in Campo de Cariñena, one of the most important cloud software architecture which stores and processes the data by means of data processing algorithms. Data Analytics e Artificial Intelligence and systems of monitoring and monitoring of the information generated for harvest managers and farmers.

From the point of view of electronic product development, we have developed a in-house electronics with the ability to precise geolocation, the ability to integrate analog and digital sensors located on carts or grape harvesters, the capacity for some distributed computing (edge analytics) and the ability to communicate over long dist ances via 4G, LTE and 5G. A power supply system has also been developed for the electronics on board the transport carts to avoid the need to recharge the battery of each device throughout the harvest.

A software approach has been used to develop a cloud software infrastructure with sufficient scale to manage one million messages during the harvest season that integrates data reception modules, data persistence in different databases, integration with the different corporate systems of Grandes Vinos y Viñedos and computing capacity for the processing of these data.

Thanks to algorithms developed with Artificial Intelligence, the data obtained from grape harvesters and transport carts are processed and the system is able to generate alarms for the harvest manager to avoid possible errors or bad practices, as well as to generate valuable information for the farmer and the wineries.

As a result of the project, the winery has successfully monitored the harvesting process in a small number of plots, carts and harvesters and plans to extend the system to all plots in order to control the harvest globally by 2021.