The services provided consist of the calibration of dimensional measuring instruments, mass calibrations and weighing instruments, calibration of force, torque and hardness measuring instruments, measurement of pressure magnitude in hydraulics and pneumatics, calibration of equipment for the generation and measurement of electrical parameters, calibration of temperature and humidity measuring and control equipment, both in a permanent laboratory and at the customer’s facilities, and metrological control of non-automatic weighing instruments.

The ITA has standards for the calibration of dimensional measuring instruments and the necessary equipment (CMM’s, profile projector, roughness meter, profilometer, etc.) to perform dimensional metrological control and surface quality of tools and parts.

Activities marked with (*) are not covered by ENAC accreditation.

ITA has the necessary means to perform mass and weighing instrument calibrations, both in the institute’s laboratories (permanent laboratory calibrations) and at the customer’s facilities (“in situ” calibrations).

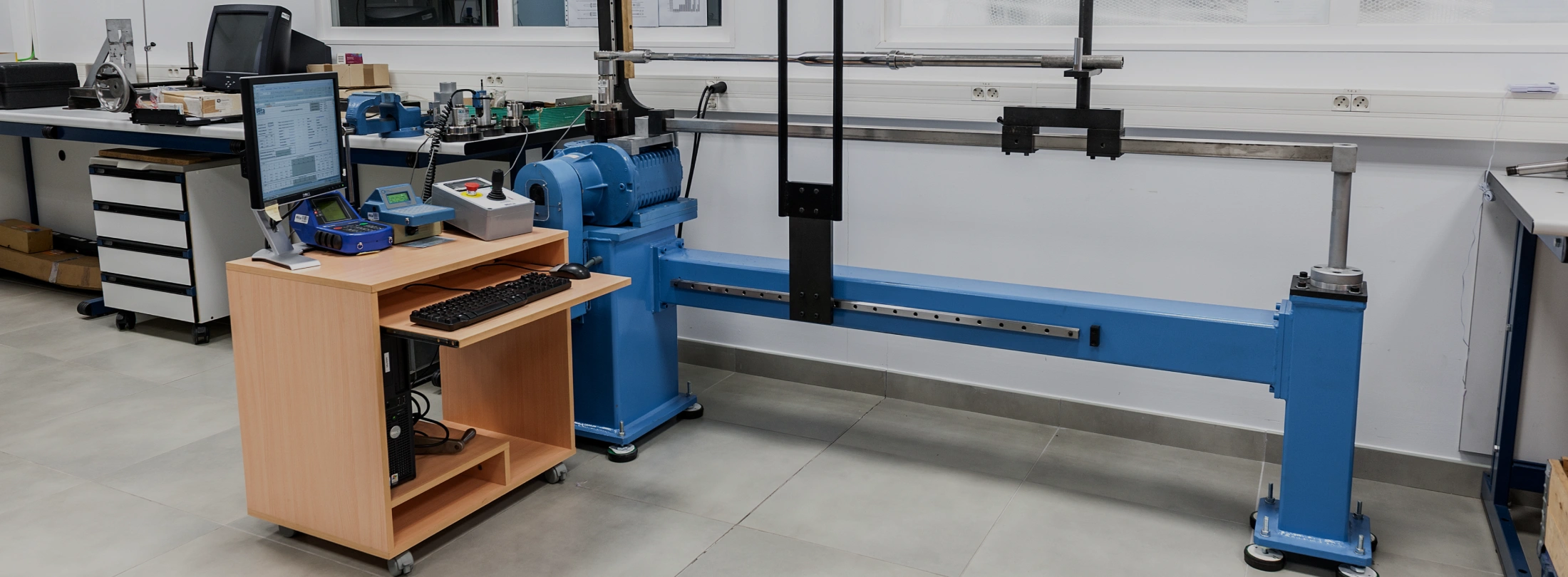

The ITA laboratory calibrates instruments for measuring force (testing machines and dynamometers), torque (dynamometric tools) and hardness (hardness testers).

Activities marked with (*) are not covered by ENAC accreditation.

(*) Dynamometers in tensile and compression directions.

(*) Brinell hardness testers by the indirect method according to Standard UNE-EN ISO 6506-2.

(*) Vickers hardness testers by the indirect method according to UNE-EN ISO 6507-2.

(*) Shore A and D hardness testers.

In the ITA we can measure the pressure magnitude in both hydraulics and pneumatics, in a wide calibration range (up to 600 bar in hydraulics and up to 20 bar in pneumatics).

In addition to performing calibrations in ITA’s laboratories (permanent laboratory), we can calibrate equipment for the generation and measurement of electrical parameters (voltage, current and resistance) at the customer’s facilities (“in situ”).

Activities marked with (*) are not covered by ENAC accreditation.

(*) Lux meters (up to 2000 lux).

The services provided consist of the calibration of temperature and humidity measurement and control equipment, both in a permanent laboratory and at the customer’s facilities, in a range from 40ºC to 1200ºC.

Activities marked with (*) are not covered by ENAC accreditation.

(*) Autoclaves.

ITA is an Inspection Entity accredited by ENAC and an Authorized Body by the Government of Aragon to carry out the metrological control of non-automatic weighing instruments.

Inspection Entity accredited by ENAC with accreditation No. 411/EI712 and Authorized Body by the Government of Aragon with registration No. 10-OV-0003 to perform metrological control in its phases of periodic verification and verification after repair or modification of non-automatic weighing instruments.

Calibration Laboratory accredited by ENAC Nº 75/LC10.050 UNE-EN ISO/IEC 17025

Testing Laboratory accredited by ENAC Nº 100/LE257- UNE-EN ISO/IEC 17025

Noise Testing Laboratory accredited by ENAC No. 100/LE 2703 - UNE-EN ISO/IEC 17025

Inspection entity accredited by ENAC No. 411/EI712 - UNE-EN ISO/IEC 17020 (NON-AUTOMATIC OPERATING WEIGHING INSTRUMENTS)

ENAC website to consult the directory of accredited entities.