Since the founding of the Instituto Tecnológico de Aragón in 1984, the Materials team has excelled in its efforts to deploy technologies that combine the materials design, development, characterization and modelingits transformation processes components and systems, as well as the design and performance verification of these systems.

The team’s vision is to develop advanced materials and new multi-scale characterization and modeling techniques for application to Materials Science and Engineering that will allow for the simple and rigorous incorporation of social and environmental effects, enabling climate-neutral developments by design.

The main objective of the Structural Integrity and Multiphysical Modeling group is to offer society and the Aragonese, national and European productive fabric solutions for the design, development and functional validation of products and systems. To this end, it makes intensive use of computational tools (finite elements, CFD, DEM) synergistically coupled with experimental validation technologies (test benches, advanced sensing, digital image correlation, monitoring of the structural health of the systems).

From the group we approach the prediction of material properties virtually through multiscale simulation to develop and apply tools and techniques to understand and predict the relationships between the process, structure, properties and function of materials. We work mainly with technical polymers, adhesives, elastomers, paper and cardboard, composite materials and metallic materials (without limitation of other types of materials – ceramics, glass, …) and with industrial orientation to the study of products where complex material behaviors may be of special relevance for the design and optimization of components; the application/selection of alternative materials for specific applications; the determination of material specifications for new climate-neutral products and the diagnosis of product failures related to material behavior.

We work to respond to the needs of the industrial environment in the use and development of polymeric-based materials, paper, composite materials, among others, adapting and improving their properties to the needs of our customers. Through the selection of materials and additives, we seek to respond to the needs of use, while trying to maintain and improve circularity and sustainability. We work on the use of resources by obtaining the highest possible yield and their reuse and incorporation into the circular chain through the different recycling options (reuse, mechanical recycling, chemical recycling or recovery). We develop our activity both in research and development projects and in those activities of innovation or technological service that complement and provide service to research. These activities include studies carried out to determine the causes of failure of materials and components in service.

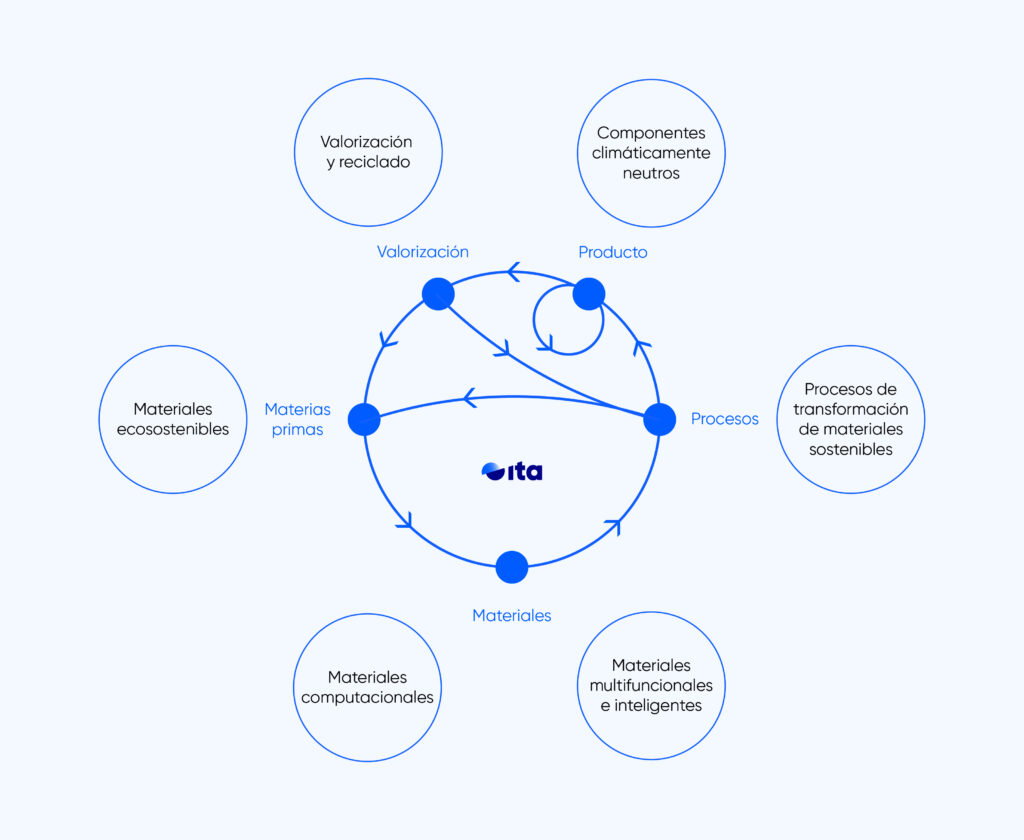

Of the eleven lines that make up the Institute’s Scientific-Technological Plan, these six are those related to the activity of the Materials and Components team:

Application of bio-based and recycled materials to industry by adapting the final properties to the end-use requirements of the products, including lifetime and recyclability and/or biodegradability conditions. The focus during this WP will be on the application of circularity to materials as well as on the basic knowledge of degradation processes and their control without loss of properties.

Development of numerical-experimental tools and strategies to accelerate the scale-up and industrialization of waste valorization and material recycling processes. Application to unit operations of solids and fluids as well as to thermochemical, electrochemical and biological processes. The emphasis in the short term will be on the implementation of a collaborative laboratory to provide companies with technologies that allow them to convert/develop climate-neutral processes.

Develop and apply tools and techniques to virtually understand and predict the relationships between the process, structure, properties and function of materials. The current focus is to contribute to the design of advanced climate-neutral materials, faster and at a fraction of the cost.

Integration of digital prototyping techniques and experimental methods to predict the functional behavior and service life of components and systems to improve the final performance of products and extend their service life. The focus during the TP will be to contribute to the competitiveness of the productive sector and environmental sustainability by making efficient use of materials and energy.

Promote, through R&D&I activities, the sustainability of materials transformation processes (existing processes and transformation of new emerging materials). The focus is on improving productivity and quality, reducing waste and energy consumption, moving towards digitization of factories and disruptive technologies such as additive manufacturing.

Technological solutions for the design, development and implementation of innovative materials incorporating new/multiple functionalities and ‘smart’ features. The focus during this WP will be on materials capable of responding in a controlled manner to certain stimuli (deformation, magnetic fields, temperature…), self-sensing and/or self-repairing materials, materials with functional gradation and/or offering improvements in certain specific properties, advanced adhesive bonds and surface texturing and coatings.

In addition, to highlight the two of Applied Research recognized by the Government of Aragon with a total of 58 effective researchers (31 of them PhDs): COMPUTAR. Climate Neutral Components, Products and Systems. DIAMOMD. Design, development and computational modeling of Advanced Materials.